Chinese Scientists Unlock Structural Secrets of Whale Baleen

Date:16-10-2018 | 【Print】 【close】

Chinese scientists working with other researchers have for the first time uncovered the underlying mechanisms of the hierarchical structure of baleen, with an eye toward developing advanced engineered materials.

Dr. WANG Bin from the Shenzhen Institutes of Advanced Technology of the Chinese Academy of Sciences, in collaboration with Professors Meyers, Sullivan and Pissarenko from the University of California, San Diego, and Professors Espinosa and Zaheri from Northwestern University (USA), revealed how underlying mechanisms of the hierarchical structure of baleen contribute to its exceptional and unique fracture behavior. The paper was published on Advanced Materials.

The ocean possesses a cornucopia of organisms that thrive through ingenious strategies, thus providing a wealth of inspiration for innovation. Baleen whales are particularly worth studying due to the many important properties of their characteristic baleen.

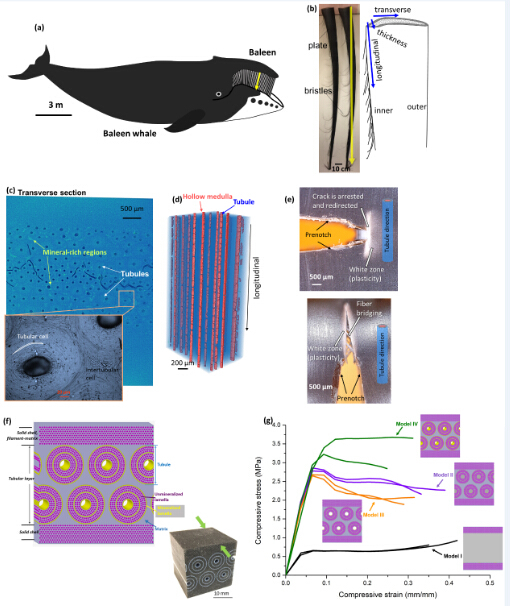

Whale baleen is the filter-feeding apparatus inside the oral cavity of mysticetes (baleen whales). It consists of a series of parallel plates suspended from the palate down both sides of the mouth and is the most mineralized material of the keratins. Baleen allows for efficient feeding on great quantities of small zooplankton. This filtering mechanism has enabled mysticetes to evolve into the largest living creatures on earth.

Taking the place of teeth, baleen withstand a lifetime of forces generated by water flow and prey, without fracturing. Indeed, fracture toughness, which measures structural integrity for reliable functioning, is a crucial material property for baleen as well as for materials utilized in marine applications.

Although rarely studied, baleen has long been known to be both strong and flexible. It was a popular material used in corsets from the 11th to the 20th centuries and has been used in Alaskan Native basketry.

Research by Prof. WANG and colleagues shows that the nanoscale structure of baleen’s intermediate filaments and mineral crystals, which are embedded in an amorphous matrix, increases its stiffness and strength. Furthermore, microscale tubular lamellae control the direction of crack propagation in case of fracture, and buckle and shear under compression. In addition, baleen’s sandwich-tubular structure boosts flexural stiffness and strength with a favorable weight saving.

"Baleen has a highly anisotropic toughness,” said Prof. Meyers. “In the longitudinal direction, cracks propagate with ease, leading to desirable delamination, fraying, and formation of bristles, necessary for the filtering action, while in the transverse direction, crack propagation is resisted by the tubular structure, providing the required resistance to water flow and prey impact.”

Quasi-static and dynamic experiments, which support the anisotropic fracture behavior of baleen, showed a ductile-to-brittle transition, with a strain rate increasing in the dry condition but absent in the hydrated condition.

Related analysis incorporating the water plasticizing effect and strain-rate stiffening provided new information on baleen behavior under competing factors of hydration and dynamic loading, which is a key consideration for designing new engineering materials for the marine environment.

Prof. WANG said it is “amazing and exciting” to study baleen from a material engineering perspective. WANG emphasized that new findings in material design related to baleen can help achieve the “ultimate goal” of developing advanced engineered materials.

Figure (a) Baleen whale and its baleen; (b) baleen plate and a schematic showing orientation; (c) micro-CT and optical images of baleen in transverse section; (d) the hollow medullae aligned longitudinally; (e) optical micrographs at the tip regions after fracture toughness tests in transverse and longitudinal loadings; (f) structural model of baleen plate, with a 3D printed one; (g) structural models I, II, III and IV with corresponding compressive behavior tested at a loading rate of 0.28 s-1.