Unlocking Sustainable Energy: Progress in Biomass-Coupled Hydrogen Production

Date:20-09-2023 | 【Print】 【close】

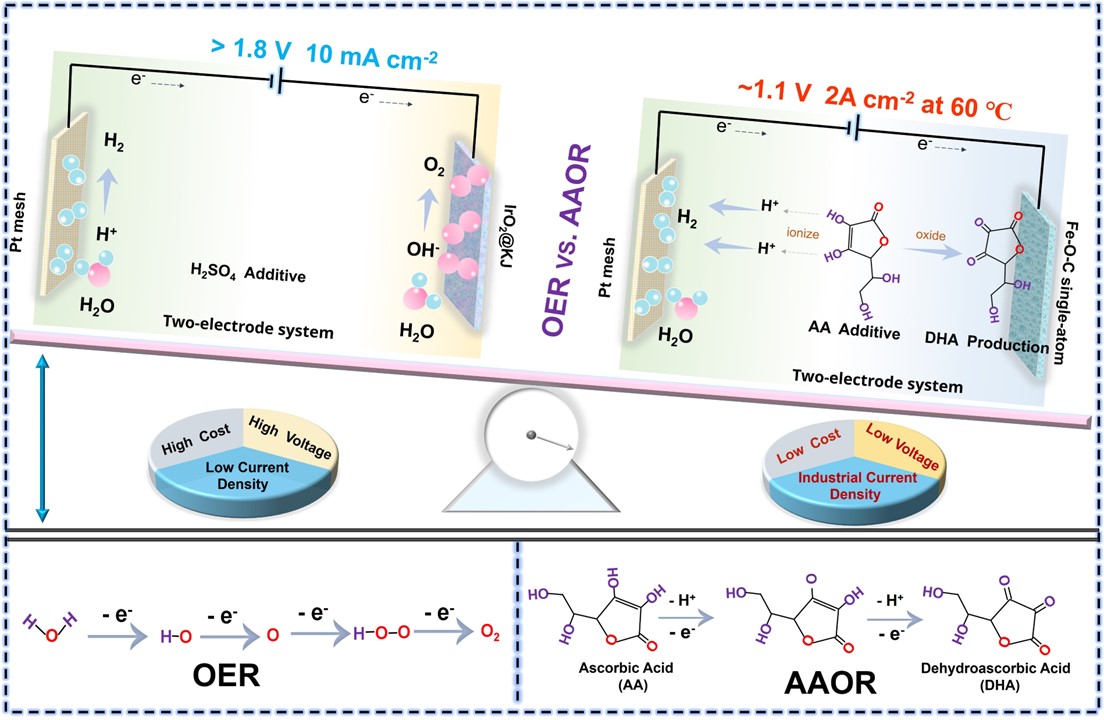

In the pursuit of a sustainable energy future, the key lies in the fusion of hydrogen production and biomass enhancement. However, most biomass electrooxidation processes have been hindered by high voltage requirements and low current density, obstructing large-scale industrial applications.

Recently, a study emerged from the collaborative efforts of Prof. CHENG Huiming and Prof. PENG Jing at the Shenzhen Institute of Advanced Technology (SIAT), Chinese Academy of Sciences (CAS). They unveiled an innovative acidic hydrogen production system that seamlessly integrates anodic ascorbic acid electrooxidation with cathodic hydrogen evolution.

Their study was published in Nature Communications on July 14.

The researchers achieved an impressive current density of 1A cm-2 in the electro-oxidation of enol biomass, requiring only a potential of 0.75 V (vs. RHE) in a pH = 2 acid solution. This remarkable feat was made possible by utilizing a Fe-O-C single-atom catalyst. Furthermore, they crafted a two-electrode electrolyzer that demonstrated extraordinary efficiency, needing only 1.1 V cell voltage to reach an industrial current density of 2 A cm-2 at 60 ℃. What's more, the electricity consumption was roughly half (2.63 kWh Nm-3 H2) that of conventional water electrolysis (5 kWh Nm-3 H2).

This groundbreaking work introduces a highly practical method for ascorbic acid electrooxidation coupled with water electrolysis, effectively eliminating the obstacles of high overpotential and low current density in biomass oxidation. It paves the way for the industrial implementation of this innovative biomass-coupled hydrogen production system.

Prof. CHENG stated, "Our study offers a promising technique for cost-effective and safe H2 production in tandem with biomass refinement. It also establishes a strong foundation for exploring other valuable enols." Compounds like phenol and catechol, known for their economic viability and increased industrial value, could potentially serve as the cornerstone for future electrooxidation-coupled electrolysis systems or even self-co-electrolysis ventures.

Schematic diagram of hydrogen production systems using oxygen evolution and ascorbic acid oxidation as anodic reaction. (Image by SIAT)

Media Contact:

ZHANG Xiaomin

Email:xm.zhang@siat.ac.cn